The Glue Talk Blog

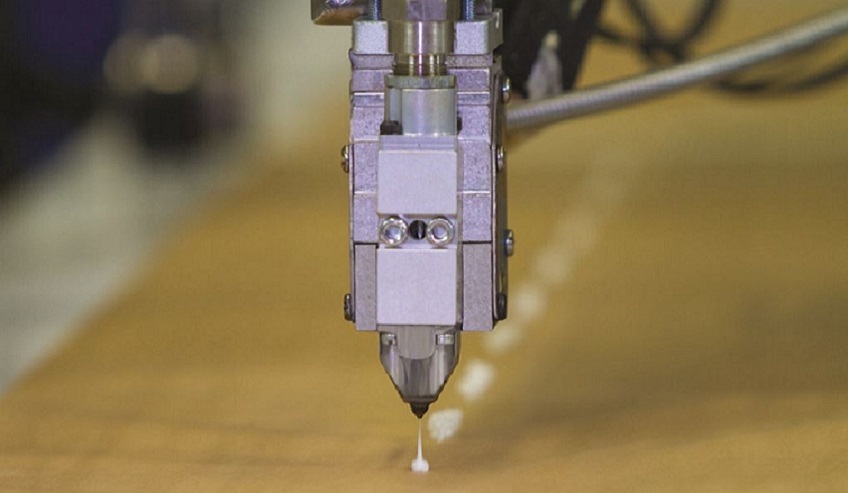

Stringing

Stringing can be identified when part of the hot melt stays on the nozzle and “strings” down the line.

- Nozzle is too far from the substrate: Adjust nozzle spacing.

- Viscosity is too high or temperature too low: Increase temperature slightly.

- Substrate temperature is too low: Allow substrates to adjust to ambient temps.

- Bead is squeezing out past the flap: Adjust bead length so adhesive stays beneath flap.

- Air pressure to Solenoid is too low: Ensure incoming air pressure is greater than 50 psi; inspect muffler buildup.

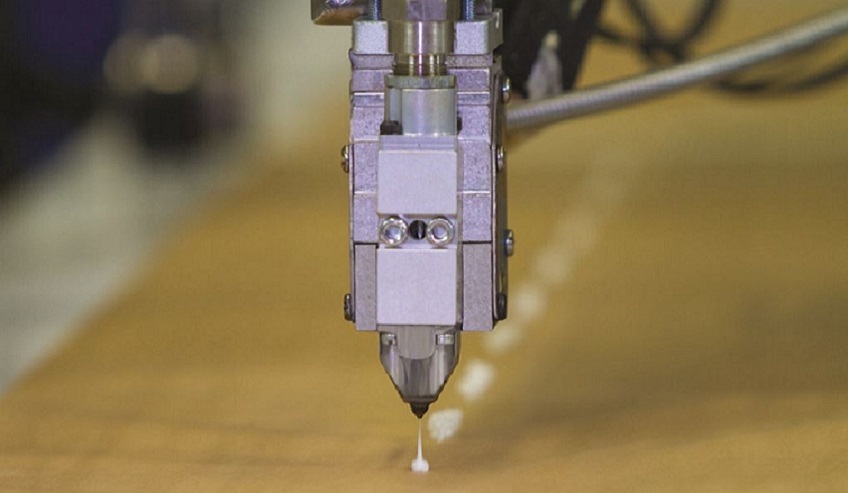

Dripping Nozzle

A dripping nozzle can be identified by hot melt flowing out of the nozzle excessively or when the applicator is off.

- Faulty module: Inspect module and replace, if necessary.

- Worn nozzles or tip: Check and replace.

- Inadequate air pressure: Increase air pressure.

Charring, Gelling or Smoking of Adhesive in Reservoir

Charring, gelling or smoking of hot melt adhesive can by identified by blackened color, thick texture and smoke coming from the reservoir.

- Temperature is too high: Check thermostat, reduce temperature, setback temperature or turn off when not in use.

- Oxidized adhesive: Replace compromised adhesive and cover reservoir.

Case Popping Open Out of Compression

Pop-opens can by identified as cases that pop open after the hot melt adhesive has been applied to seal the case.

- Adhesive is cooling too slowly or too much adhesive is applied: Decrease application temperature and pressure.

- Not enough hot melt applied: Increase temperature and pressure.

- Substrates shift under compression: Adjust machine settings.

Poor Penetration or Adhesive Failure

Poor penetration can be identified by low or no adhesive applied to the substrate.

- Poor penetration, temperature too low: Increase temperature.

- Not enough hot melt is applied: Increase pressure or nozzle size.

- Poor or excessive compression, wrong product: Adjust compression, evaluate application.

- Hot melt temperature is fluctuating: Keep reservoir full and covered, lift hoses off cold floor.

Bubbles in Hot Melt

Bubbles can appear on the applicator and on the substrate.

If the bubbles are on the applicator

- Moisture in the tank or adhesive: Inspect tank and adhesive.

- Damaged or open valve is allowing air into system: Check valve and replace if defective.

If the bubbles are on the substrate

- Moisture in substrate is causing vapor boil-out: Check by applying adhesive to dry substrate (metal or other) and dry out substrate.

Click here to download our hot melt adhesives troubleshooting guide, complete with photos.

Blog Categories

Archive

- 2024

- 2023

-

2022

- February (4)

- March (3)

- April (1)

- May (2)

- June (5)

-

August (6)

- Beverage Labeling Market In Africa: A Huge Potenial

- H.B. Fuller’s Glue House: Scavenger Hunt

- Increasing Global Aging Population: Impacts and Challenges

- Innovations and Key Challenges in Sustainable Disposable Absorbent Hygiene Products

- Supporting Racial Equity in Our Community

- Top 5 Reasons to Invest in H.B. Fuller

- September (4)

- November (2)

- December (2)

-

2021

- January (3)

-

February (7)

- Celebrating Exceptional Service During COVID-19 Complications

- Cyanoacrylates: What They Are and What They Do

- Innovative two-shot bookbinding adhesive

- Make a Difference 2020

- Problem Solving: Paper straws in drinking beverages

- Stronger straws

- Substances of Interest in Disposable Absorbent Hygiene Products

- March (4)

- April (4)

- May (4)

- June (5)

- July (2)

- August (5)

- September (2)

- October (1)

- November (3)

- December (2)

-

2020

- January (4)

- February (2)

- March (3)

- April (4)

- May (3)

-

June (7)

- Community Support in the Era of Coronavirus

- Employee Creates Face Shields with 3D Printer

- Improved Packaging Integrity and Greater Customer Satisfaction

- Liquid-Resistant Paper Straws

- What is a Sealant

- What Is the Future of Commercial Disinfectants

- Winning over consumers with e-commerce packaging solutions

-

July (6)

- Employees Take Action to be Part of Healing and Growth

- Gain a competitive advantage with packaging adhesive solutions

- HB Fuller Company Foundations Commitment to Communities

- Packaging Solutions for the South African Agriculture Market

- Supporting Organizations That Provide STEM Education for Youth

- Where Does Sustainability Stand Amid COVID-19

- August (3)

- September (2)

- October (4)

- November (2)

- December (4)